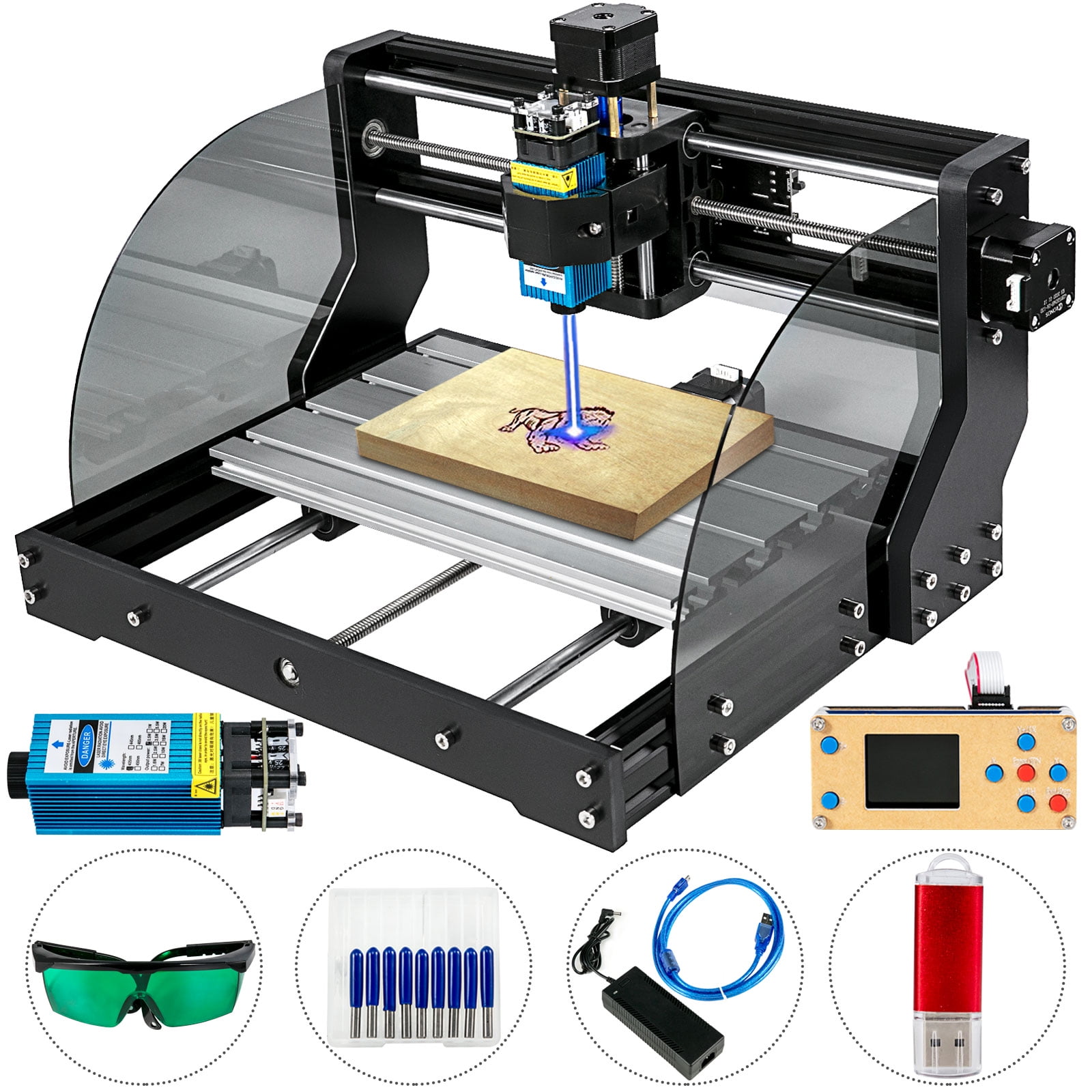

Because the hardness of the wood material is relatively large, in general, woodworking engraving machines need to be equipped with a spindle motor with a higher power. At present, there are many manufacturers and brands of such equipment on the market, and the price will be affected by the brand. The brand of the engraving machine is different.The price gap of stone CNC Router machine is large, mainly affected by the following factors: The price range is generally between 2,000USD and 15,000USD. The CNC router stone engraving machine is mainly used for engraving marble, granite, jade, blue-stone, black stone, and other stone materials, as well as ceramics, glass, organic glass, PVC board, aluminum-plastic board, bamboo, and other materials. Ask the price to compare with each other to see which one should be selected. Some are because they already know this product. Some people are just for high prices and quality. The price is a question that most people will ask in advance when buying goods. At the same time, by milling, you can engrave various planes or three-dimensional graphic characters designed on the computer to realize automatic engraving processing.

CNC ROUTER MACHINE SERIES

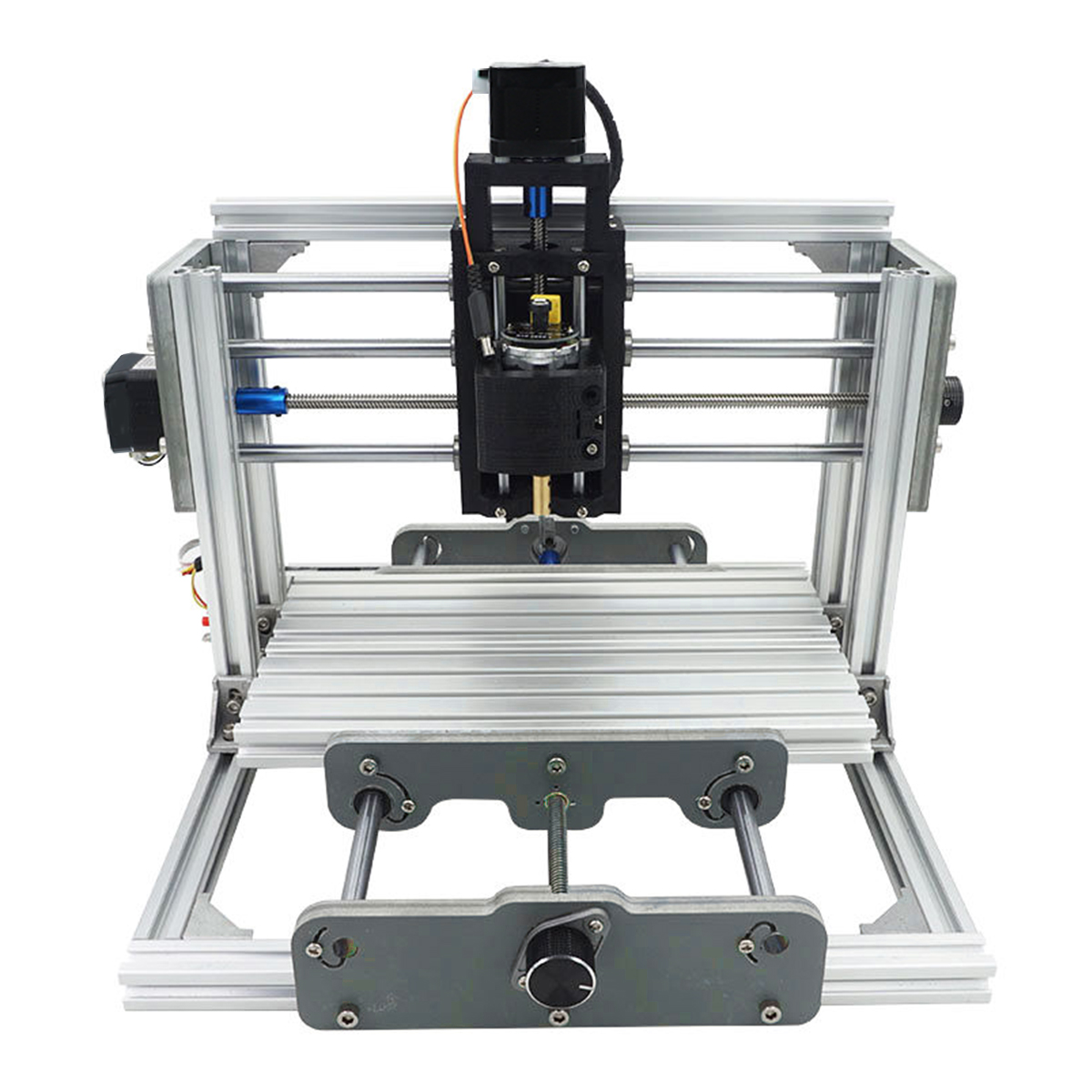

After the CNC system receives the tool path data and completes a series of functions such as display and user interaction, it uses a specific algorithm to convert the input path information into CNC information, and the controller converts this information into drive The signal (pulse train) of the stepper motor or servo motor controls the x, Y and Z axes of the engraving machine. The interface transmits the tool path data to the single-chip microcomputer.

CNC ROUTER MACHINE SOFTWARE

Investing in a good dust collector is important keeping the machine components free of dust and debris which can cause damage over time.The stone CNC Router machine is a three-dimensional numerical control system, and its working principle is shown in the figure: special design and typesetting software are installed in the general microcomputer to design and typeset graphics and text, automatically generate processing path information, and transmit it through a USB interface or other data.

cabinet making software if this is your primary business. Consider application specific software packages e.g. Invest in software that provides advanced features and regular updates. Software: A CNC machine will only do what it is programmed to do.Table Size: Buy a CNC router machine that is large enough to handle your typical material size while also considering room for growth.Automatic Tool Changer (ATC): If your application requires using multiple tools, then an ATC system would greatly speed up tool changes, reduce operator error and significantly decrease job times.Also look at the spindle manufacturer as the quality of the spindle is critical. Look at the capabilities of the spindle including HP, RPM, torque, power requirements, load ratings, collet type.

0 kommentar(er)

0 kommentar(er)